PROGRAMMES OFFERED

All our courses as well as syllabus is accredited by BTEC (Business and Technology Education Council) which is one of United Kingdom’s longest running practical and skilled based learning centre of excellence recognised globally.

FOUNDATION LEVEL

LEVEL 1

LEVEL 2

- BTEC Customised Programme in Engineering Operations for Oil and Gas Facilities - Level 2 Electrical

- BTEC Customised Programme in Engineering Operations for Oil and Gas Facilities - Level 2 Instrument

- BTEC Customised Programme in Engineering Operations for Oil and Gas Facilities - Level 2 Mechanical

- BTEC Customised Programme in Engineering Operations for Oil and Gas Facilities - Level 2 Process

LEVEL 3

- Pearson BTEC International Level 3 Specialist Diploma in Control Room Operations in Oil and Gas Facilities

- Pearson BTEC International Level 3 Specialist Diploma in Electrical Engineering Operations in Oil and Gas Facilities

- Pearson BTEC International Level 3 Specialist Diploma in Instrument Engineering Operations in Oil and Gas Facilitie

- Pearson BTEC International Level 3 Specialist Diploma in Mechanical Engineering Operations in Oil and Gas Facilities

4 DISCIPLINES

CONTROL ROOM OPERATIONS (CRO)

Job function:

To control, monitor and shutdown of oil and gas production, both manually and using computerised distributed control systems. Technicians are responsible for maintaining safe operations and achieving production targets.

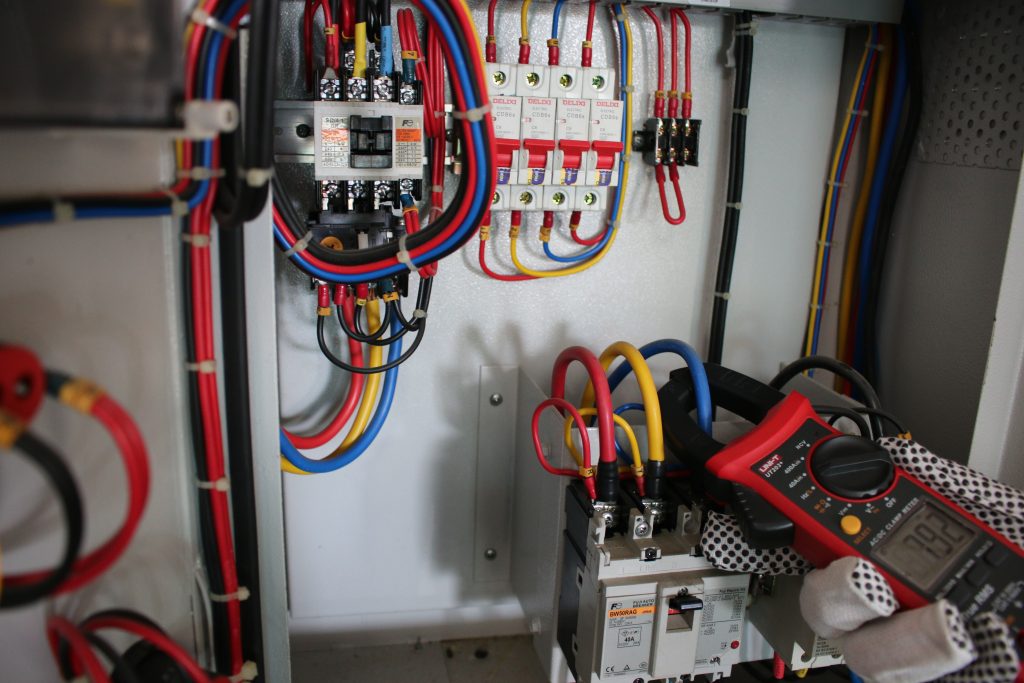

ELECTRICAL ENGINEERING OPERATIONS

Job function:

Inspecting, testing and maintaining electrical installation and equipment, as well as, maintaining a range of power, distributions, utilities and protection systems in oil and gas facilities.

MECHANICAL ENGINEERING OPERATIONS

Job function:

Technicians are responsible for operating and performing maintenance on the static equipment, engines, pumps, turbines and compressors in oil and gas facilities.

INSTRUMENT ENGINEERING OPERATIONS

Job function:

Regulate and maintain measurement systems for oil and gas flow, level, pressure and temperature. They are also responsible for electronic and pneumatic process control systems and safeguarding systems.

LEVEL 3 - CONTROL ROOM OPERATOR (CRO)

3.1 PERFORM FUNCTIONAL TESTING OF INTEGRATED PROCESS SYSTEMS AND REMOTE CONTROL OPERATIONS

- Understand the functions and operating principles of processes and equipment

- Operate panel hardware for the distributed control system(DCS), programmable logic controller(PLC) or instrument protective system(IPS)

- Understand key process control loops and safeguarding systems

- Be able to control the production process and prepare equipment for normal operation and maintenance

3.2 PERFORM CENTRAL CONTROL ROOM OPERATIONS

- Understand alarm management

- Understand cause and effect of safety critical loops

- Be able to access critical information and report anomalies

- Be able to manage and coordinate control room operations

3.3 COORDINATE THE RESPONSE TO EMERGENCIES AND CRITICAL PROCESS SITUATIONS

- Be able to assess critical situations within the work area and react appropriately

- Be able to coordinate the response to emergencies

3.4 PERFORM CONSTITUENTS TESTING OF PROCESS FLUIDS

- Understand the testing of different constituents in oil and gas fluids

- Be able to perform constituent testing of fluids

- Be able to prepare samples for further laboratory testing

3.5 MAINTAIN FLOW ASSURANCE ON SUBSEA WELLS

- Understand the functions and principles of subsea systems

- Be able to start up and maintain the operations of a subsea well

- Be able to perform a normal subsea well shutdown

3.6 OPERATE AND MAINTAIN SUBSEA SYSTEMS

- Be able to perform subsea well testing

- Be able to perform subsea well annulus monitoring and bleed down

- Be able to perform a subsea wellhead valve leak test

- Be able to operate a subsea chemical injection system

- Be able to operate and maintain a hydraulic system

LEVEL 3 - ELECTRICAL

3.1 INSPECT AND TEST INSTALLATIONS, CABLES AND CONDUCTORS

- Be able to switch and isolate electrical wiring installations

- Be able to inspect, test and evaluate the condition of electrical wiring installations

- Be able to rectify faulty electrical wiring installations

3.2 INSPECT AND TEST POWER DISTRIBUTION AND PROTECTION SYSTEMS

- Be able to switch and isolate a distributions and protection system

- Be able to inspect, test and evaluate the condition of electrical distribution and protection systems

- Be able to rectify faulty electrical distribution and protection systems

3.3 PERFORM CORRECTIVE MAINTENANCE OF ELECTRICAL EQUIPMENT AND DISTRIBUTION SYSTEMS

- Be able to collect and evaluate information and data to identify faults in electrical equipment and distribution systems

- Be able to dismantle faulty equipment or assemblies

- Be able to replace or repair faulty equipment or systems and reassemble them

- Be able to evaluate and commission reassembled equipment and distribution systems

3.4 PERFORM CORRECTIVE MAINTENANCE OF AUXILIARY POWER AND UTILITIES SYSTEMS

- Be able to collect and evaluate information and data to identify faults in auxiliary power and utilities systems

- Be able to dismantle faulty equipment or assemblies

- Be able to replace or repair faulty equipment or systems and reassemble them

- Be able to evaluate and commission reassembled equipment in auxiliary power and utilities systems

3.5 PERFORM CORRECTIVE MAINTENACE OF POWER GENERATION AND PROTECTION SYSTEMS

- Be able to collect and evaluate information and date to identify of faults in power generation and protections systems

- be able to dismantle faulty equipment or assemblies

- Be able to replace or repair faulty equipment or systems and reassemble them

- Be able to evaluate and commision reassembled equipment in power generation and protection systems

LEVEL 3 - MECHANICAL

3.1 PERFORM CORRECTIVE MAINTENANCE OF RECIPROCATING ENGINES

- Be able to coordinate and plan for the service and repair of a reciprocating engine

- Be able to service, repair, adjust a defective engine

- Be able to rectify faulty electrical wiring installations

3.2 PERFORM CORRECTIVE MAINTENANCE OF PUMPS

- Be able to coordinate and plan for the service and repair of a pump

- Be able to service, repair and adjust a defective pump

- be able to carry out pump troubleshooting

3.3 PERFORM CORRECTIVE MAINTENANCE OF GAS TURBINES

- Be able to coordinate and plan for the service and repair of a gas turbine

- Be able to service, repair and adjust a defective gas turbine

- Be able to carry out gas turbine troubleshooting

3.4 PERFORM CORRECTIVE MAINTENANCE OF COMPRESSORS

- Be able to coordinate and plan for the service and repair of a compressor

- Be able to service, repair and adjust a defective compressor

- Be able to carry out compressor troubleshooting

LEVEL 3 - INSTRUMENT

3.1 PERFORM CORRECTIVE MAINTENANCE OF CONTROL SYSTEMS AND SAFEGUARDING SYSTEMS

- Be able to carry out checks on the process measuring and controlling equipment used in the process control system

- Be able to carry out checks on the instrument devices and equipement used in the turbine and compressor control systems

- Be able to carry out checks on the process measuring and controlling equipment used in the instrumented protective functions devices

- Be able to carry out checks on the fire and gas detection devices and equipment used in the fire and gas system

3.2 PERFORM CORRECTIVE MAINTENANCE OF DISTRIBUTED CONTROL SYSTEMS

- Be able to perform loop checks on the distributed control system(DCS)

- Be able to perform tests on the DCS system

- Be able to analyse data to rectify faults identified

3.3 PERFORM CORRECTIVE MAINTENANCE OF INSTRUMENTED PROTECTIVE DEVICES AND SYSTEMS

- Be able to perform loop checks on the instrument protective system(IPS)

- Be able to perform tests on the IPS system

- Be able to analyse data to rectify faults identified

3.4 PERFORM CORRECTIVE MAINTENANCE OF FIRE AND GAS DETECTION DEVICES AND SYSTEMS

- Be able to perform loop checks on the fire and gas(FNG) detection system

- Be able to perform tests on the FNG system

- Be able to analyse data to rectify faults identified

ASSESSMENT STRUCTURE

PROGRAMME

ASSESSMENT STRUCTURE

ASSESSMENT PROCESS

FOUNDATION

LEVEL 1

60% on Coursework

40% on Final Exam

1. Assignments

2. Presentations

3. Quizzes

4. Mid-Term Exam

5. Final Exam

LEVEL 2

LEVEL 3

30% on Coursework

70% on In-House Training (Level 2)

and On-Job-Training (Level 3)

1. Observation Record/ Witness Statement

2. Field Assignment Report

3. Oral Test

4. Written Test

5. Compilation of Portfolio

There are four main courses available in TAS Institute which are :

- Control Room Operations

- Mechanical Engineering

- Instrument Engineering

- Electrical Engineering

The courses are divided across four levels which is :

- Foundation

- Level 1 Multi Skill Certificate

- Level 2 Intermediate Certificate

- Level 3 Specialist Diploma

Student can apply to further their education with SPM holder as the minimum qualification.

FOUNDATION

BTEC CUSTOMISED PROGRAMME IN OIL & GAS OPERATIONS – FOUNDATION

Entry Requirement:

SPM Holder (Malaysia), Senior Cambridge Education “SCE”, United Kingdom accredited “O” levels or other equivalent recognized qualifications with credits in English, Mathematics, Science & ONE other subject.

Duration of the course : 3 (three) months

This course is develop for students who do not possess the minimum entry requirements to Level 1. This three months course is designed to develop their basic knowledge in engineering thus ensuring their ability to progress to the next levels.

LEVEL 1

BTEC CUSTOMISED PROGRAMME IN OIL & GAS OPERATIONS – LEVEL 1

Entry Requirement :

TAS Foundation Certificate, General Certificate of Education (“GCE”) accredited “A” levels or STPM Holder (Malaysia) or equivalent, or Diploma/ Degree in relevant Engineering field with CGPA 2.8 and above.

Duration of the course : 6 (six) months

This multi-skill introductory level focuses on the introduction to Oil & Gas Exploration and Production. Students are taught on the four disciplines that is Process Engineering Mechanical Engineering, Instrument Engineering, Electrical Engineering practised by the Oil & Gas industry.

LEVEL 2

BTEC CUSTOMISED PROGRAMME IN OIL & GAS OPERATIONS – LEVEL 2 ELECTRICAL

BTEC CUSTOMISED PROGRAMME IN OIL & GAS OPERATIONS – LEVEL 2 INSTRUMENT

BTEC CUSTOMISED PROGRAMME IN OIL & GAS OPERATIONS – LEVEL 2 MECHANICAL

BTEC CUSTOMISED PROGRAMME IN OIL & GAS OPERATIONS – LEVEL 2 CONTROL ROOM OPERATIONS

Entry Requirement :

TAS Level 1 Certificate

Duration of the course : 6(six) months

Students who are accepted to Level 2 shall have the option to select a specific discipline of their choice. Students at Level 2 are taught and trained to specialise in the operations of equipments being used in the oil and gas industry in their respective discipline. This shall both comprise of classroom based and in-house laboratories and on-the-job training.

LEVEL 3

PEARSON BTEC INTERNATIONAL LEVEL 3 SPECIALIST DIPLOMA IN ELECTRICAL IN OIL & GAS FACILITIES

PEARSON BTEC INTERNATIONL LEVEL 3 SPECIALIST DIPLOMA IN INSTRUMENT IN OIL & GAS FACILITIES

PEARSON BTEC INTERNATIONAL LEVEL 3 SPECIALIST DIPLOMA IN MECHANICAL IN OIL & GAS FACILITIES

PEARSON BTEC INTERNATIONAL LEVEL 3 SPECIALIST DIPLOMA IN CONTROL ROOM OPERATIONS IN OIL & GAS FACILITIES

Entry Requirement :

TAS Level 2 Certificate.

Duration of the course : 6(six) months

In this level students will focused on-the-job training (“OJT”) for a period of 3 months before they proceed with their portfolio preparation and assessment by internal assessors as well as international verifies from United Kingdom (“BTEC”)